Sandwich panel

Contents |

[edit] Introduction

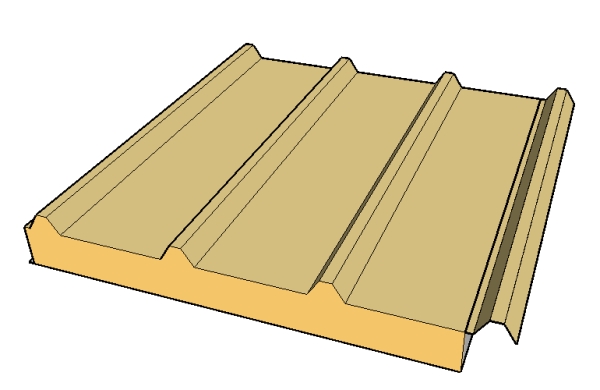

Sandwich panels (sometimes referred to as composite panels or structural insulating panels (SIP)) consist of two layers of a rigid material bonded to either side of a lightweight core. The three components act together as a composite; that is, the combination of the characteristics of the components results in better performance than would be possible if they were acting alone.

The lightweight core keeps the two faces in the correct position, resists shear forces, and provides insulation, while the two faces provide durability, weather and impact resistance, and resist in-plane forces of tension and compression.

Sandwich panel systems include the panels themselves, the joints between them, fixings (often concealed) and a support system.

[edit] History and development

Composite cladding systems have been in use for a considerable time, in particular for the manufacture of vehicles such as trains and planes, but the development of advanced sandwich panels for cladding buildings first began in the 1930’s, when they were researched by organisations such as the Forest Products Laboratory, and used by architects including Frank Lloyd Wright. They went on to become increasingly popular following the second world war.

Modern sandwich panels can be flat, bent, curved and joined together in an almost unlimited range of configurations and are available in a wide variety of colours, finishes, thicknesses, edge details and profiles depending on performance requirements.

They are generally fabricated off-site and are particularly useful where a high-performance cladding is required, with good structural strength, a high level of insulation and low weight.

[edit] Uses

Sandwich panels are widely used as an external cladding for single and multi-storey buildings, where they are required to provide weather resistance, and resistance to wind-loading, access loads, self-weight and so on. However, they are also used to create insulated internal envelopes, ceiling panels, partitions (for example in cold stores) and for fire-resisting compartment walls.

Building types that commonly feature sandwich panels include:

- Industrial buildings and processing plants.

- Temporary buildings.

- Storage buildings.

- Clean rooms.

- Agricultural buildings.

- Shopping centres.

- Sports facilities.

- Transport buildings.

[edit] Materials

The outer faces of sandwich panels are most commonly made of metals such as:

However, other materials that can be used include:

- Precast concrete, sometimes clad with other finishes such as brick.

- Cement board.

- Glass fibre reinforced polypropylene.

- Poly vinyl chloride (PVC).

- Magnesium oxide board (MgO).

- Plywood.

- Oriented strand board (OSB).

- Glass reinforced plastic (GRP).

Cladding systems typically include a rigid polyurethane core, but other core materials include:

- Expanded polystyrene (EPS).

- Extruded polystyrene (XPS).

- Mineral wool (rock fibre) (MWRF).

- Modified Phenolic foam (MPHEN).

- Polyisocyanurate (PIR).

- Folded metal, paper, aramid and carbon fibres. See Foldcore for more information.

- Honeycomb materials (such as Polypropylene).

[edit] Properties

Sandwich panels can be selected because of their:

- Ease and speed of installation.

- Rigidity.

- Thermal, fire and sound insulation.

- Airtightness

- Robustness and durability

- Low maintenance / cleaning requirements.

- Low capital cost.

- Low lifetime costs

- Chemical and biological resistance

- Light weight.

- Weather resistance.

- Dimensional stability.

- Availability as standard products off-the-shelf.

However, There can be particular difficulties associated with buildings containing combustible sandwich panels. For more information see Fire performance of sandwich panel systems, Association of British Insurers, May 2003.

[edit] Related articles on Designing Buildings Wiki

- Building fabric.

- Cladding.

- Composites.

- Curtain wall systems.

- Foldcore.

- Glazing.

- Metal composite panels.

- Metal profile cladding.

- Polyurethane spray foam in structurally insulated panels and composite structures.

- Precast concrete cladding.

- Rainscreen.

- Structural Insulated Panels.

- Wall types.

- Weatherboarding.

Featured articles and news

Infrastructure that connect the physical and digital domains.

Harnessing robotics and AI in challenging environments

The key to nuclear decommissioning and fusion engineering.

BSRIA announces Lisa Ashworth as new CEO

Tasked with furthering BSRIA’s impressive growth ambitions.

Public buildings get half a million energy efficiency boost

£557 million to switch to cleaner heating and save on energy.

CIOB launches pre-election manifesto

Outlining potential future policies for the next government.

Grenfell Tower Inquiry announcement

Phase 2 hearings come to a close and the final report due in September.

Progress from Parts L, F and O: A whitepaper, one year on.

A replicated study to understand the opinion of practitioners.

ECA announces new president 2024

Electrical engineer and business leader Stuart Smith.

A distinct type of countryside that should be celebrated.

Should Part O be extended to existing buildings?

EAC brands heatwave adaptation a missed opportunity.

Definition of Statutory in workplace and facilities management

Established by IWFM, BESA, CIBSE and BSRIA.

Tackling the transition from traditional heating systems

59% lack the necessary information and confidence to switch.

The general election and the construction industry

As PM, Rishi Sunak announces July 4 date for an election.

Eco apprenticeships continue help grow green workforce

A year after being recognised at the King's coronation.

Permitted development rights for agricultural buildings

The changes coming into effect as of May 21, 2024.

Comments